E-waste—the massive volume of discarded electronics in the form of smartphones, digital screens and other electronic devices—is a global crisis. Less than a quarter of the 62 million tons of e-waste produced annually is successfully recycled.

Part of this glut originates from design engineers that prototype electronic circuit boards used for new products. Modern prototyping tools have allowed for the quick production of these testbed circuit boards, often with little afterthought for addressing their end-of-life impacts.

Researchers from the University of Maryland, University of Notre Dame and Georgia Institute of Technology are now working on a viable solution, developing a fully recyclable printed circuit board that dissolves when immersed in water.

Known as DissolvPCB, this novel fabrication method is low-cost and accessible, and can be created using a standard Fused Deposition Modeling (FDM) 3D printer, several of which can be found in makerspace labs on the UMD campus.

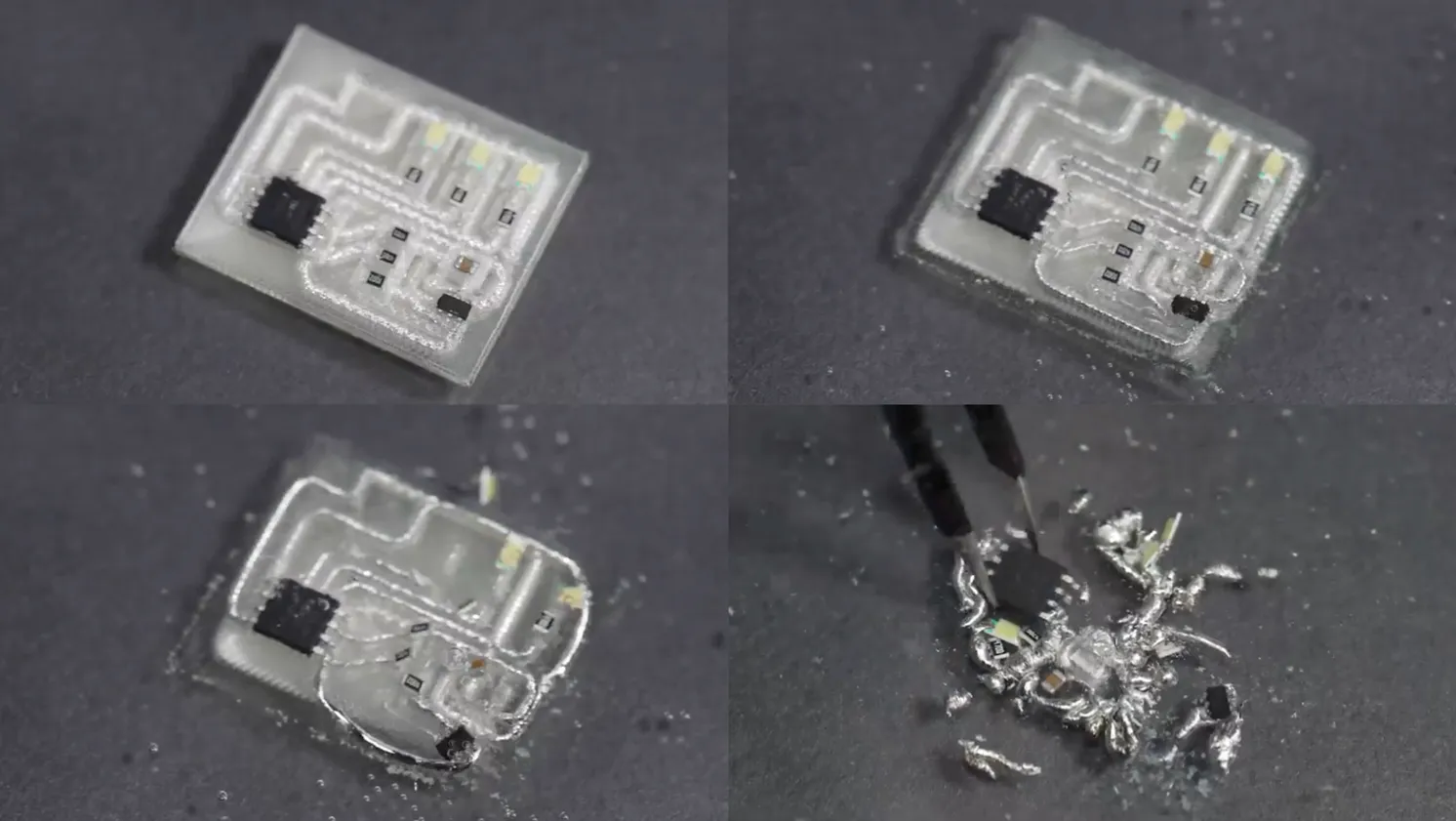

How does it work? The circuit board uses a water-soluble synthetic polymer known as PVA as the substrate and a liquid metal alloy known as EGaIn as the conductor material. At the end of its life, the printed circuit board is simply placed into water, where the PVA dissolves and the EGaIn material gathers into a reusable liquid metal bead that can be easily recovered to fabricate another circuit board.

In their initial testing, the multi-institutional team—led by the University of Maryland—found that their method achieved a more than 98% material recovery rate.

The researchers just presented a paper outlining their method at the ACM Symposium on User Interface Software and Technology (UIST) in South Korea, where it won a Best Paper award. It was one of only six papers from the more than 900 submitted to receive this recognition.

DissolvPCB also received Special Recognition for Sustainability in the Demos category at UIST. In addition, the researchers have released an open-source plugin for designing recyclable electronics.

This recovery method for printed circuit boards could be just the first step in rethinking how electronics used for computing are manufactured and recycled, says Zeyu Yan, a fifth-year computer science Ph.D. student at UMD who was lead author of the study.

The team’s broader goal is to have circuit boards used for smartphones or larger devices produced in the same locale where the device’s final assembly takes place.

This can help bypass any delays caused by the sometimes-fragile global supply chain risk involving electronics, where a circuit board intended for an MRI machine manufactured in Europe is produced in China and shipped halfway around the world before being installed.

“Eventually, our vision is that all the materials that go into these computational devices can be locally produced and locally recycled,” Yan says.

The DissolvPCB technology could also lower the cost barrier for sustainable printed circuit board production, says Huaishu Peng, an assistant professor of computer science who is Yan’s academic adviser.

Peng, who has an appointment in the University of Maryland Institute for Advanced Computer Studies (UMIACS), explains that anyone with access to an FDM 3D printer and the inexpensive materials used by the UMD team can quickly start making their own recyclable circuit boards.

“I hope to convince people that this approach is not only more sustainable, but could also be more economically beneficial for them,” Peng says.

Assisting on the DissolvPCB project are Su Hwan Hong, who is currently pursuing his master’s in computer engineering at UMD and who presented the demo at UIST; Tingyu Cheng, an assistant professor of computer science and engineering at the University of Notre Dame; and Josiah Hester, an associate professor of computing at the Georgia Institute of Technology.

Peng noted that working with the researchers at Georgia Tech and Notre Dame made a big difference. “We were able to move forward and iterate between different ideas and solutions very quickly because of this cross-institutional collaboration,” he says.

While their project is certainly on the right track, the researchers say there are still challenges ahead. This includes the fact that while the design of their water-soluble circuit board is computerized, its assembly, disassembly and recycling process still requires manual effort.

“We’re currently trying to build automated machines so that you could dump in a circuit, and it comes out ready to reuse,” Yan explains.

He says the research team hopes to get their DissolvPCB technology out into the community for others to use soon, noting the need for more user feedback and open-source improvements that can benefit everyone moving forward.

“We want to see makerspaces other than those on the University of Maryland campus using this,” Yan says. “We’re hoping to see feedback from the electronics manufacturing community saying that this technology is important for their sustainability efforts.”

—Story by Zsana Hoskins, UMIACS communications group